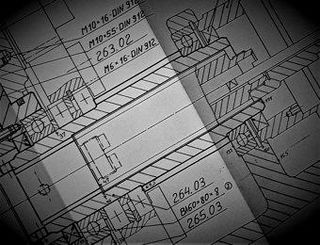

Considering the current prices for turned parts, investing into a new machine may not always make sense. However, the original condition of your existing, worn out machine can in most cases be restored for a fraction of the costs compared with a new purchase.

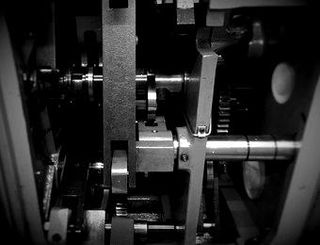

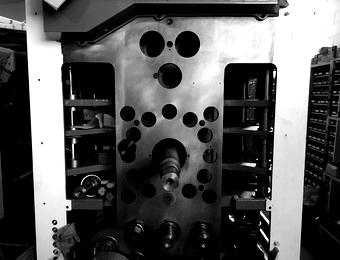

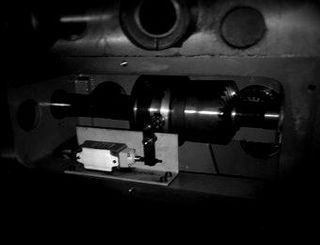

In our house the machine is disassembled completely and assembled again with all necessary new parts. Often existing construction parts can be recycled; for example a chromed bearing seat of a curve shaft has a higher loading capacity than a new part. The electrics are renewed completely and replaced by a control that really meets your wishes. The new varnish is adapted to your colour concept. All kinds of conversions and additional fittings are possible, just contact us ! If this effort does not suit you, a geometrical partial overhaul is also possible, most times these works can even be carried out on your premises; necessary reworks e. g. regrinding the carriage can be made in our house at the same time. The costs for all works are either based on an hourly basis, or on a pre-determined fixed price. Just call us and we will come over for a free and non-binding visit in order to get a picture of the possibilities.